Adding a water pressure indicator to an OMC outboard.

Tell-tale, tale-tell, pee-stream, pee-hole, that little squirty thing -- later model OMCs have 'em and you want one on yours.

The water pump is a crucial element in preserving the health of your

outboard. It's vitally important to know that it's functioning

properly. That's where the water pressure indicator comes in. It

functions by tapping into the water-jacket in your powerhead and

providing a visible relief outlet, or "pee stream". The outlet is

small, and has limited flow so water pressure is still maintained

in the powerhead and doesn't all escape via the indicator.

To retrofit the indicator, you'll need to tap a hole for a fitting in

your powerhead's water jacket, put a hole in your lower cowling for a

bulkhead indicator fitting and run a hose between the two.

If you have an early 80s or late 70s motor, it may be adviseable to

relocate, or modify the routing of the indicator's plumbing. Service

bulletins have been included in the appropriate engine section where

available. Included is a section on modifications at the end of the FAQ

to cover some of these procedures.

Adding the indicator outlet to the block

OMC's early tell-tale equiped motors tapped into the bottom of the

water jacket through the exhaust cover for the indicator's source. It

was later realized that tapping in high up on the powerhead had the

added benefit of removing any air-pockets in the cooling system, as

well as draining the entire system after use. The latter has

substantial benefit for winter storage in cold climes. Most later model

OMCs had their tell-tale outlets located high up on the exhaust cover

for these reasons.

In retro-fitting a tell-tale, you have many choices for locating the

indicator outlet on the block. Certainly, the exhaust cover is one, but

on some blocks there are better choices. Wherever you choose to locate

it, higher is better.

At the chosen location you'll need to drill an 11/32" hole and tap it

with a 1/8" pipe tap. This will accept either the OEM outlet elbow

(P#321886 0r Sierra # 18-3290), or a 1/8" threaded bronze nipple from

the hardware store. All of these accept a 3/16" to 5/16" ID hose (P#

321887, 913435, or 327721) that

will run to a bulk-head fitting (P# 0321885) through the lower cowling. When

drilling the hole, apply grease to the drill bit to capture any metal

shavings, and be sure to use a light oil on the tap so the threads are

cut properly.

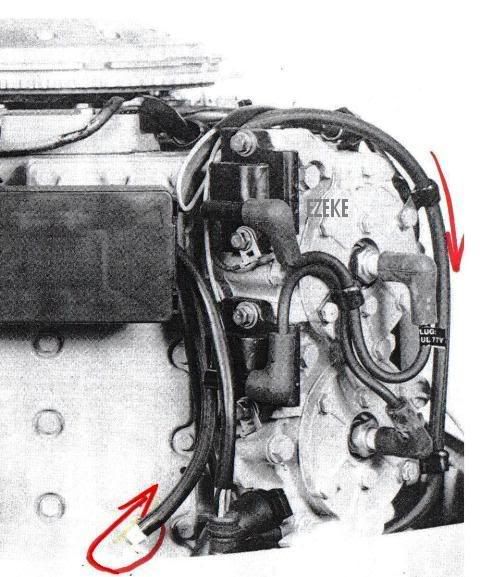

V-4 blocks

The V-4 configuration presents some interesting issues for locating the

indicator outlet. Typically the V-4s run hot on the starboard side.

That's because of a tendency to develop air pockets high up on cylinder

#1. By adding the indicator outlet to the top of the water jacket above

cylinder #1 you provide an opportunity to "burp" any air out of the

system and fix this issue. On many of the '73-'77 V-4 blocks there's a

cast-in round boss just perfect for locating the indicator outlet. If

you don't happen to have that boss, you can go in through the top, just

behind the coil brackets also.

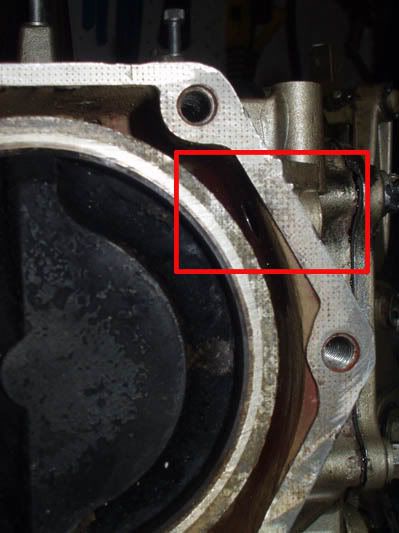

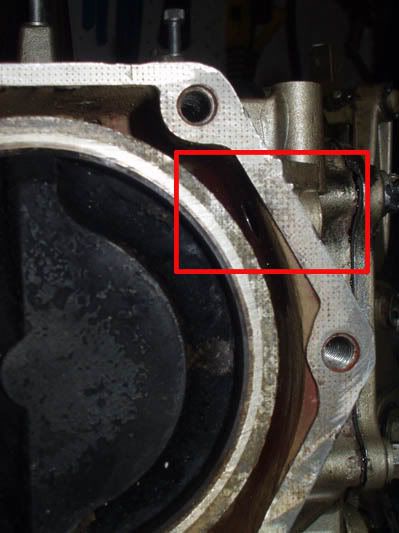

Location of the cast-in boss w/ hole tapped.

This location puts the outlet at a high spot in the cooling jacket.

Also, since it's to the side of the block, it's easier to route to the

side of cowling for the bulkhead fitting than an outlet located on the

exhaust cover.

Using the boss provides access high up on cylinder #1's water jacket.

Inline 3-Cylinder Blocks

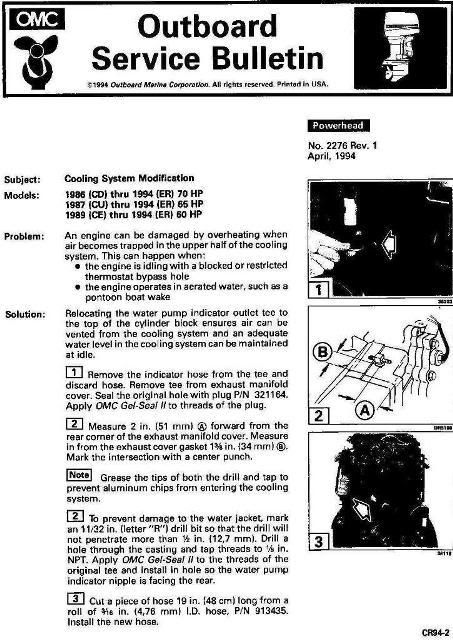

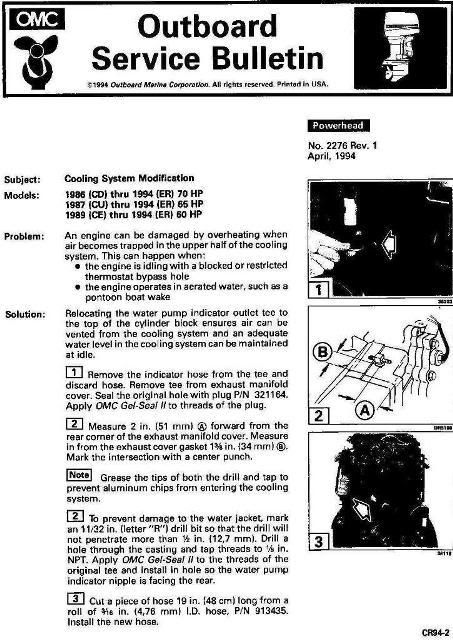

The recommendation for the inline threes is to place the indicator at

the top of the cylinder block as per the following service bulletin.

Even inline threes with factory installed tell-tales are advised to

relocate from the exhaust cover to the top of the cylinder.

Inline 2-Cylinder Blocks

Mounting the lower cowling bulkhead fitting

Now that you've got the outlet fitting in the powerhead, you need a way

to make the output visible on the outside of the motor. This is done by

drilling a hole in the lower cowling and attaching the OEM indicator

cowling fitting (P #321885) in a place that will be easily visible.

This is usually placed in the rear of the lower cowling on the

starboard side.

Lower cowling fitting

This fitting clips into a 11/16" hole. Now, not all of us have drill

bits that big. You can get by with drilling a smaller hole and making

an oval for the two clips with a small round file.

The fitting then simply clips into the hole from the outside of the lower cowling.

Indicator outlet lower cowling bulkhead fitting from the outside

Indicator outlet lower cowling bulkhead fitting from the inside

Routing the hose

Now that you've got both fittings in place, you just need to connect

them up with a hose. If you have not tapped the powerhead outlet into

the very top of the #1 cylinder, it is adviseable to route the hose in

such a way that some part of the hose raises above the powerhead. This

will prevent air pockets from forming in the powerhead and creating hot

spots. Use zip-ties to clamp the hose onto the fittings, or leave

unclamped. There is very little pressure on the hose and it won't leak

if it's in good shape.

Adviseable Modifications to Early Systems

Service Bulletins

Service buletins containing re-location or re-routing instructions

specific to engine type are located above in the followign sections:

Other Modifications

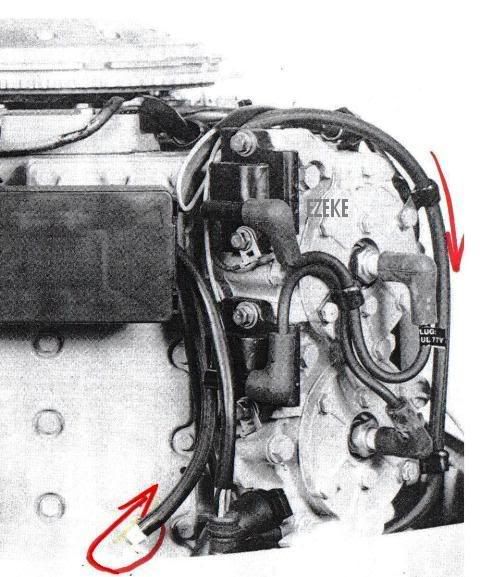

Many of the early systems tapped into the water jacket at low point,

and ran the outlet hose straight down to the bulkhead fitting. This

configuration can cause air bubbles to enter the water jacket and cause

hot-spots.

Early OMC low-placed outlet with direct drain

If you don't want to relocate the outlet to a higher spot on the

engine, it is adviseable to re-route the hose over the engine block to

prevent air from entering the system.

The Short and Sweet

- Drill 11/32" hole in powerhead providing access to the water jacket, thread with 1/8" pipe tap.

- Fit 1/8" pipe fitting with 5/16" nipple into the hole using either

- Outlet elbow (P#321886 0r Sierra # 18-3290)

- Similar bronze fitting

- Drill 11/16" hole in lower cowling.

- Fit bulkhead fitting (P# 0321885) in place from the outside.

- Run a 3/16" to 5/16" ID hose (P#

321887, 913435, or 327721) connecting the powerhead fitting to the bulkhead fitting.